Empowering People with Smarter Technologies

In lean manufacturing lingo, "Gemba" is the shop floor, the place where the work happens, and the place where value is created (sometimes also referred to as the "place of truth"!). Gemba Systems' mission is to empower people on the shop floor with smarter technologies that support and enable better processes, resulting in higher productivity, better quality, and improved morale.

About Gemba Systems

Our Mission

In lean manufacturing lingo, "Gemba" is the shop floor, the place where the work happens, and the place where value is created (sometimes also referred to as the "place of truth"!). Gemba Systems' mission is to empower people on the shop floor with smarter technologies that support and enable better processes, resulting in higher productivity, better quality, and improved morale.

Our Offerings

Gemba Systems Inc. supports manufacturing companies in the digitalization of their operations, especially focused on improving their manufacturing execution systems. We help companies navigate the complex and fast-evolving landscape of “smart manufacturing” and the Industrial Internet of Things. We offer guidance, tools, and hands-on support in the selection and implementation of those Industry 4.0 technologies that will best support our clients' most critical business processes, and the people who perform them.

Aligning People, Processes, and Technology

In order to create more value, companies need to reduce waste, reduce variation, and improve their responsiveness and agility. To achieve this, they need well-trained people, performing well-defined and controlled processes, assisted by capable, fit-for-use, and reliable technology. We help companies achieve better performance by putting in place more effective production systems consisting of well-aligned people, processes, and technology.

Solutions we Offer

Real-Time Location Systems

“Real-Time Location System” is a technology used to track and locate objects or people in real time within a defined space, such as a factory, warehouse, hospital, or office building. RTLS solutions typically use technologies like RFID, Bluetooth, UWB (Ultra-Wideband), Wi-Fi, GPS, or infrared to determine the location of a tag attached to an asset or person.

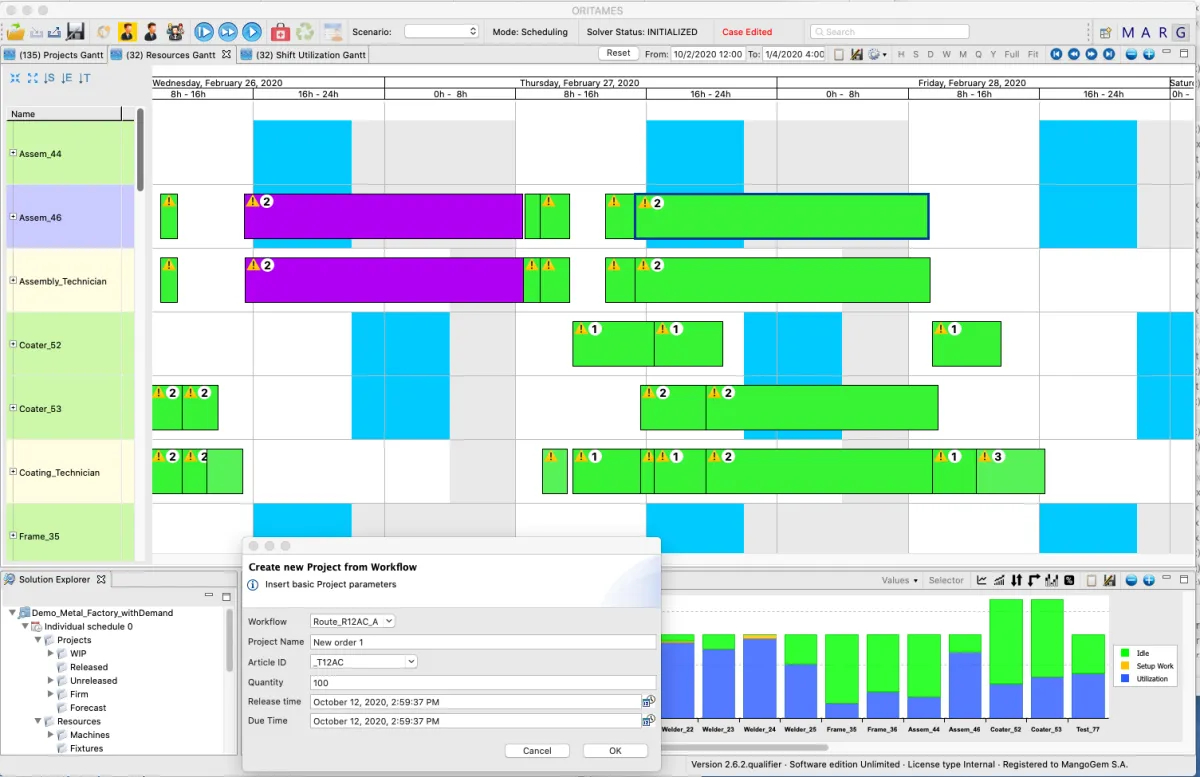

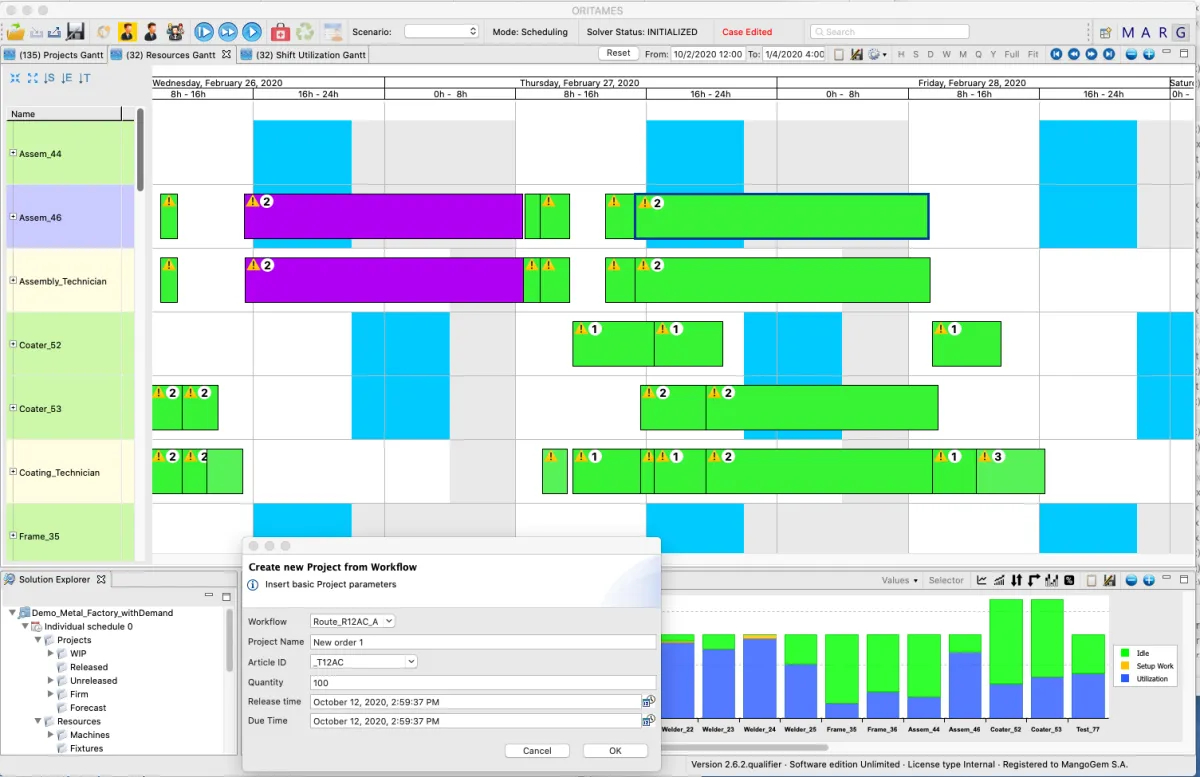

Advanced Planning and Scheduling

Advanced Planning and Scheduling (APS) solutions enable fast, flexible, and realistic production scheduling and material requirements planning, including advanced optimization, user-friendly interface, and powerful reporting, for significantly better throughput, shorter lead times, and improved on-time delivery, with less inventory, less work-in-progress, and less fire-fighting.

Advanced Planning and Scheduling

Advanced Planning and Scheduling (APS) solutions enable fast, flexible, and realistic production scheduling and material requirements planning, including advanced optimization, user-friendly interface, and powerful reporting, for significantly better throughput, shorter lead times, and improved on-time delivery, with less inventory, less work-in-progress, and less fire-fighting.

JANE DOE !!

From strategic SEO optimization to targeted social media campaigns, they had a solution for every challenge. Thanks to their expertise, my revenue has doubled in just six months.

JANE DOE !!

Working with [Your Marketing Agency's Name] was a game-changer for my small business. Their team's dedication and creative approach breathed new life into our brand.

JANE DOE !!

Their data-driven insights and marketing strategies have consistently exceeded our expectations, resulting in significant ROI. I highly recommend them to any business

FAQs

What does Gemba Systems do?

Gemba Systems helps manufacturers improve productivity and profitability through real-time tracking, RFID automation, and lean-focused process improvements.

What can I track with your RTLS solutions?

We enable tracking of raw materials, WIP, tools, bins, pallets, forklifts, equipment, trailers, returnable packaging, employees, and more - with accuracy ranging from rough zones to inches-level precision.

What tracking technologies do you offer?

We work with UWB, BLE, RFID, and GPS. We recommend the best-fit technology based on your use case, budget, and environment.

How accurate is your system?

UWB and BLE AoA offer accuracy within inches. RFID and BLE beacon solutions are ideal for zone-based tracking. We help you balance cost, infrastructure, and accuracy.

Do you support lean manufacturing initiatives?

Absolutely. Our solutions directly reduce waste (motion, waiting, inventory) and support tools like FIFO, SMED, e-Kanban, and time & motion studies.

Do you integrate with existing ERP or MES systems?

Yes. We offer easy integrations with your enterprise systems, enabling automatic transactions, alerts, and workflows based on real-time location data.

Can I combine multiple technologies in one system?

Yes. Our platform supports hybrid deployments - combining UWB, BLE, RFID, and GPS - to meet varying needs across your facility.

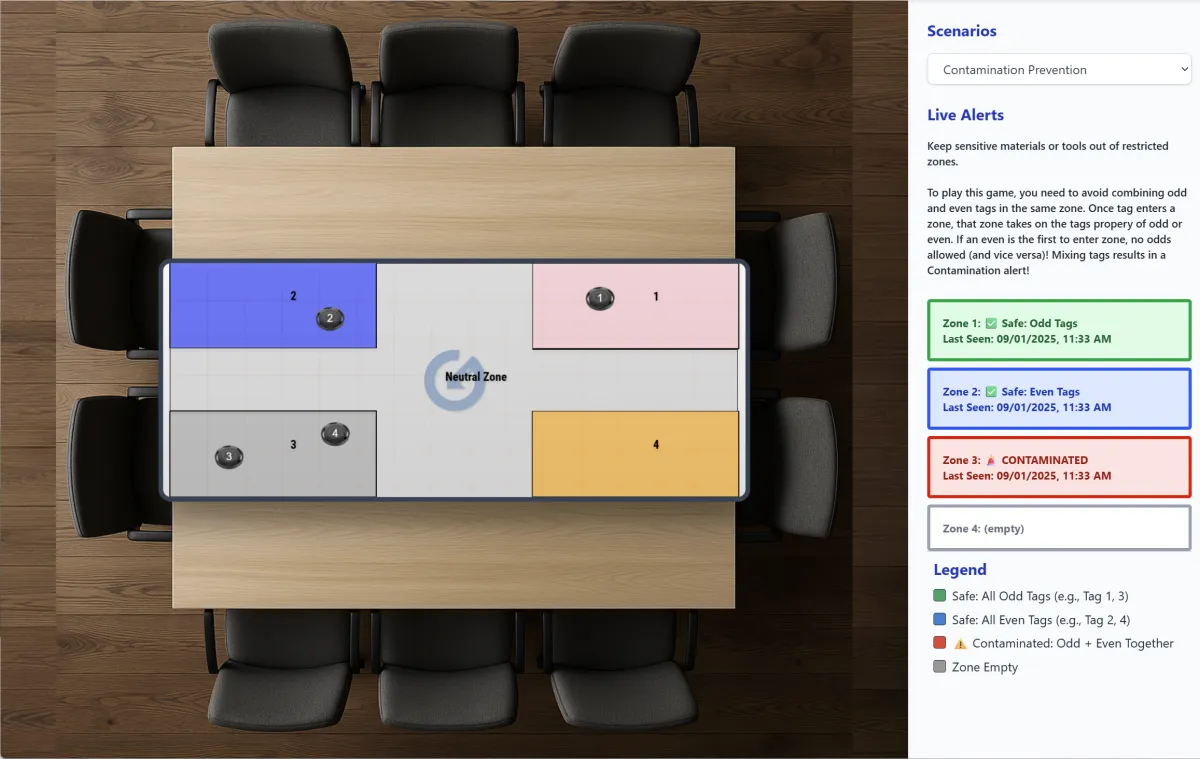

Play our Track and Trace Game!

🔍 Ever lost a cart of WIP mid-process?

🛠️ Wonder where your tools actually are during a shift?

⏱️ Or just curious how RTLS can help make real-time decisions... really real-time?

We built the Track and Trace Game to bring Manufacturing to life, on a tabletop, with scenarios that mirror real shop floor challenges. It’s hands-on and designed to help teams see what’s really happening in their operations and how to drive improvement through better visibility and control.